AJICURE

Product list

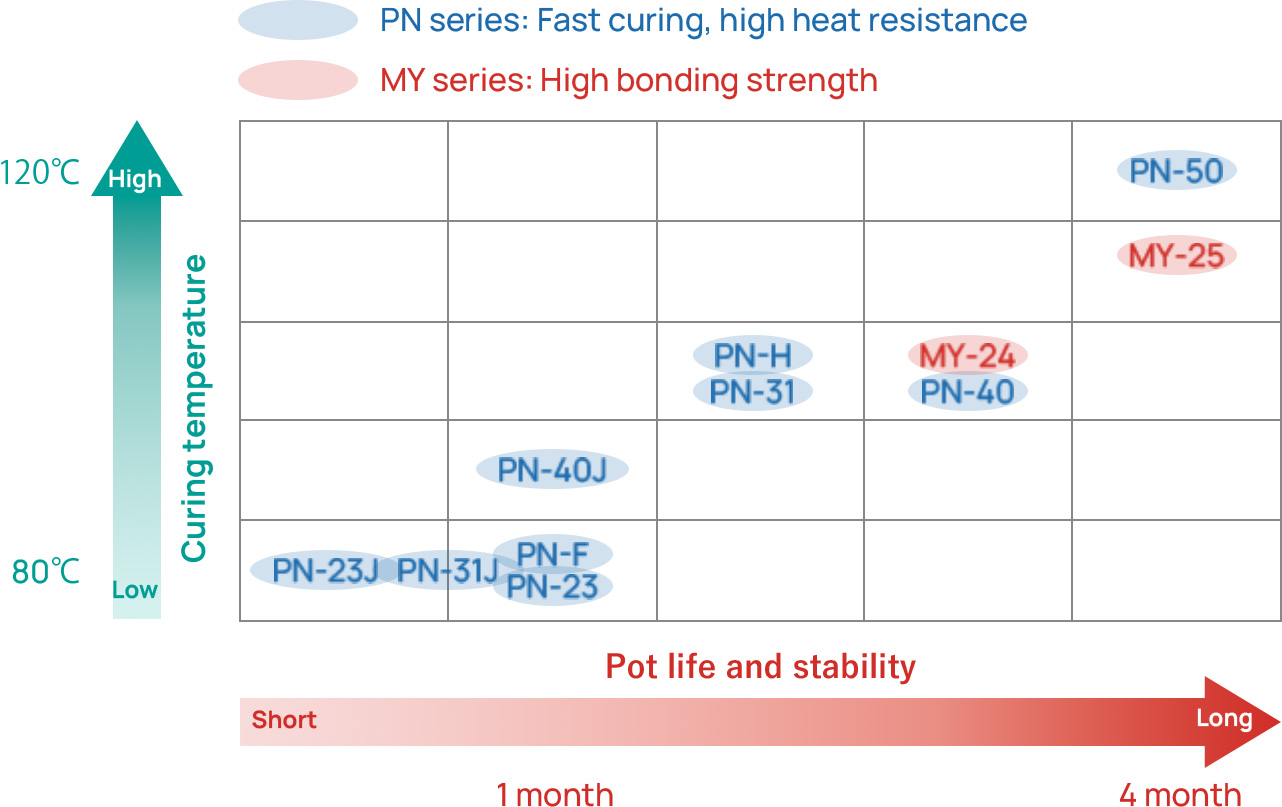

Variety of AJICURE

| Grade | Type | Softening point |

Dosage*1 | Gel time*2 | Curing condition*3 |

Storage stability*4 |

Remarks |

| PN-23 | Amine adduct | 100ºC | 20(1~5) | 4 min.(100ºC) |

80ºC x 30 min. |

1 month |

Rapid cure at a low temp., resistant to heat |

| PN-23J | Amine adduct | 100ºC | 20(1~5) | 4 min.(100ºC) |

80ºC x 30 min. |

2 weeks | Super-fine particles, rapid cure at a low temp., resistant to heat |

| PN-31 | Amine adduct | 115ºC |

20(1~5) | 5 min.(100ºC) |

100ºC x 30 min. |

2 months |

Longer pot life with Bisphenol F epoxy resin, than PN-H |

| PN-H | Amine adduct | 115ºC | 20(1~5) | 5 min.(100ºC) |

100ºC x 30 min. |

2 months |

Improved storage stability ahead of PN-23 |

| PN-40 | Amine adduct | 110ºC | 20(1~5) | 6 min.(100ºC) |

100ºC x 30 min. |

3 months | Stable pot life with Bisphenol F epoxy resin |

| PN-40J | Amine adduct | 110ºC | 20(1~5) | 4 min.(100ºC) | 90ºC x 30 min. |

1 month | Super-fine particles imparting luster with longer pot life |

| PN-50 | Amine adduct | 115ºC | 20(1~5) | 7 min.(120ºC) | 120ºC x 30 min. |

4 months | The most stable & longest storage stability. Can be kneaded at 90ºC (stable at a high temp.) |

| PN-50J | Amine adduct | 115ºC | 20(1~5) | 6 min.(120ºC) | 110ºC x 30 min. |

3 months | Super-fine particles imparting luster with long pot life |

| MY-24 | Amine adduct | 120ºC | 20(1~5) | 5 min.(100ºC) | 100ºC x 60 min. |

3 months | Stable pot life, superior adhesiveness, luster |

| MY-H | Amine adduct | 130ºC | 20(1~5) | 5 min.(100ºC) | 110ºC x 60 min. |

4 months | Improved pot life ahead of MY-24 |

| MY-25 | Amine adduct | 130ºC | 20(1~5) | 12 min.(100ºC) | 110ºC x 60 min. |

4 months | for automotive, and structural materials. Regular Package: 25kg Fiber Drum |

| VDH | Hydrazide | 120ºC | 41 | 20min.(110ºC) | 110ºC x 60 min. |

1 week | Materializes colorless transparent cured product with thermal resistance |

| UDH | Hydrazide | 150ºC | 48 | 8 min.(150ºC) |

130ºC x 60 min. |

1 month | Generate less heat in curing, low elasticity |

| AH-123 | Complex | 120ºC | 45 | 5 min.(120ºC) |

120ºC x 30 min. |

1 month | Flexible |

| AH-203 | Complex | 130ºC | 25 | 5 min.(100ºC) |

90ºC x 60 min. |

1 month | High shear bond strength, less coloration |

| AH-154 | DICY | 200ºC | 9 | 8 min.(150ºC) |

150ºC x 60 min. |

3 months | Good hardness, thermal resistance |

| AH-162 | DICY | 200ºC | 11 | 3 min.(150ºC) | 150ºC x 60 min | 3 months | Superior pot life at high temperatures |

| *1 | Dosage: against a certain dosage of liquid epoxy resin equivalent to 190 epoxy, dosage as accelerator is shown in parentheses ( ) |

| *2 | Gel time: measured by AJICURE mixture including a certain amount Bisphenol A epoxy resin equivalent to about 190 epoxy, determined temp is shown in parentheses ( ) |

| *3 | Curing condition: measured by AJICURE mixture including a certain amount of Bisphenol A epoxy resin equivalent to about 190 epoxy |

| *4 | Storage stability: measured by AJICURE mixture including a certain amount of Bisphenol A epoxy resin equivalent to about 190 epoxy at 40ºC until the viscosity is double |

Note: All technical data herein described corrected by AJICURE mixtures without any other additives and auxiliaries.

Test methods introduced for the technical data:

|

|